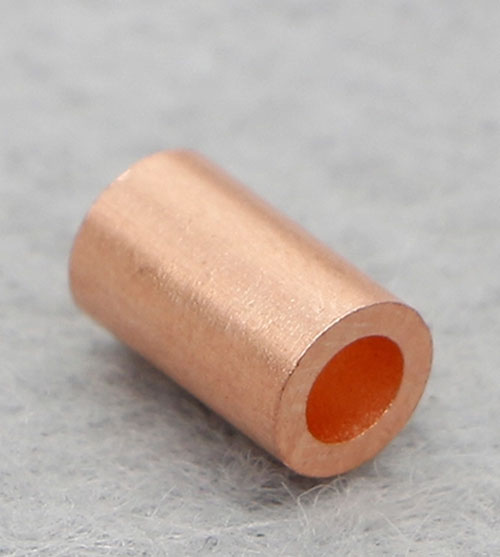

- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

Cu 99.95% min

Schedule 40 wall: ½” to 4”

Schedule 80 wall: 1” to 3”

| Trade Name | C103 Copper Pipe, C103 Copper Tube |

|---|---|

| Available Material |

|

| Standards | ASTM B188, ASME SB188 |

| Specification | OD:2mm~914mm, WT:0.2mm~120mm |

| Outer Diameter | 2mm~914mm |

| Thickness | 0.2mm~120mm |

| Length | 1m, 2m, 3m, 4m, 6m, or as required, 1m, 2m, 3m, or as required |

| C103 Copper Tubing Sizes | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| Wall Thickness | 0.2mm~120mm |

| Color | Golden |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| C103 Copper Pipe Length | Single Random, Double Random, Standard & Cut length |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Available Forms | Coil, Round, Square, Rectangular, Boiler, Hydraulic, Hollow, Straight or ‘U’ bent Tubes, LSAW Tubes Etc. |

| C103 Copper Tube Type | Seamless, Welded, Fabricated, ERW, EFW |

| Hardness | 1/6 hard, 1/8 hard, 3/8 hard, 1/4 hard, 1/2 hard, full hard, soft, etc |

| Alloy Or Not | Non-alloy |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| End | Plain End, Beveled End, Treaded |

| Marking | All C103 Copper tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Surface | mill, polished, bright, hair line, mirror, brush, sand blast, etc |

| Specialize supplier of |

|

| Supply Ability | 3000 Metric Ton/Metric Tons per Month standard size in stock |

| Value Added Service |

|

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

Container Size |

|

| Export market | Malaysia, Saudi Arabia, Singapore, Indonesia, Ukraine, Spain, Canada, USA, Brazil, Iran, Russia, Chile, Thailand, Korea, Egypt, Oman, Ireland, England, Mexico, Peru, Italy, Nigeria, Kuwait, Egypt, Holland, Vietnam etc |

| Tube Size | Tube Length | Wall Thickness | Inside Dia. | Outside Dia. |

|---|---|---|---|---|

| 5/32" | 6 ft. | 0.014" | 0.125 | 5/32" |

| 3/16" | 6 ft. | 0.014" | 0.125 | 3/16" |

| 7/32" | 6 ft. | 0.014" | 0.191 | 7/32" |

| 1/4" | 5 ft. | 0.035" | 0.250" | 3/8" |

| 1/4" | 10 ft. | 0.035" | 0.250" | 3/8" |

| 3/8" | 2 ft. | 0.049" | 0.375" | 1/2" |

| 3/8" | 5 ft. | 0.049" | 0.375" | 1/2" |

| 3/8" | 10 ft. | 0.049" | 0.375" | 1/2" |

| 1/2" | 2 ft. | 0.049" | 0.500" | 5/8" |

| 1/2" | 5 ft. | 0.049" | 0.500" | 5/8" |

| 1/2" | 10 ft. | 0.049" | 0.500" | 5/8" |

| 5/8" | 2 ft. | 0.049" | 0.625" | 3/4" |

| 5/8" | 5 ft. | 0.049" | 0.625" | 3/4" |

| 5/8" | 10 ft. | 0.049" | 0.652" | 3/4" |

| 3/4" | 2 ft. | 0.065" | 0.750" | 7/8" |

| 3/4" | 5 ft. | 0.065" | 0.750" | 7/8" |

| 3/4" | 10 ft. | 0.065" | 0.750" | 7/8" |

| 1" | 2 ft. | 0.065" | 1.000" | 1-1/8" |

| 1" | 5 ft. | 0.065" | 1.000" | 1-1/8" |

| 1" | 10 ft. | 0.065" | 1.000" | 1-1/8" |

| 1-1/4" | 10 ft. | 0.065" | 1.250" | 1-3/8" |

| 1-1/2" | 10 ft. | 0.072" | 1.500" | 1-5/8" |

| 2" | 10 ft. | 0.083" | 2.000" | 2-1/8" |

| 2-1/2" | 10 ft. | 0.095" | 2.500" | 2-5/8" |

| 3" | 10 ft. | 0.109" | 3.000" | 3-1/8" |

| 4" | 10 ft. | 0.134" | 4.000" | 4-1/8" |

7-10 US$ PER KG.

Price is subject to change without any notification, please contact SMI Copper for final price of C103 Copper Tube

| ASTM B188 C10200 OFHC Annealed Tube | C10200 Copper ACR Tube |

| C10200 Copper seamless Tube | ASTM B188 OFHC C103 Welded Pipe |

| ASTM B188 OFHC C103 Capillary Tube | C103 Copper Coil Tube |

| C103 Copper Seamless Pipe | C10200 Copper Welded Tube |

| C103 Copper Braid Tube | Inner Grooved C103 Copper Copper Tube |

| C10200 Copper Finned Tube | C103 Copper Condenser Tube |

| C103 Copper U-Bend Tube | C103 Copper Exhaust Tubing |

| ASTM B188 OFHC C103 Square Tube | ASTM B188 OFHC C103 Gas Tube |

| Large diameter C103 Copper Tube | C10200 Copper Straight Pipe |

| Thin wall C103 Copper Tubing | Thin wall C103 Copper Tube |

| ASTM B188 C10200 OFHC Tubing 1/8 | C10200 Copper Exhaust Tube |

| Elements | Min % | Max % |

|---|---|---|

| Bi | 0.001 | |

| Cu | 99.95 | |

| Pb | 0.005 |

| Property/unit | Condition | Min | Max |

|---|---|---|---|

| Tensile Strength (N/mm2) | O | 260 | |

| Elongation in 5.65Cross sectional area | O | 32 | |

| Tensile Strength (N/mm2) | 1/2H | 290 | |

| Elongation in 5.65Cross sectional area | 1/2H | 4 | |

| Tensile Strength (N/mm2) | H | 350 |

| Above | 2.5mm | – | 3mm | + | 0-0.04mm |

|---|---|---|---|---|---|

| Above | 3mm | - | 6mm | + | 0-0.05mm |

| Above | 6mm | – | 10mm | + | 0-0.06mm |

| Above | 10mm | – | 18mm | + | 0-0.07mm |

| Above | 18mm | – | 20mm | + | 0-0.052mm |

| Above | 20mm | – | 30mm | + | 0-0.08mm |

| Above | 30mm | – | 50mm | + | 0-0.16mm |

| Above | 50mm | – | 80mm | + | 0-0.19mm |

Alloy | Joining Technique | Suitability Level |

|---|---|---|

C10200 | Soldering | Excellent |

Brazing | Excellent | |

Oxyacetylene Welding | Fair | |

Gas Shielded Arc Welding | Good | |

Coated Metal Arc Welding | Not Recommended | |

Spot Weld | Not Recommended | |

Seam Weld | Not Recommended | |

Butt Weld | Good | |

Capacity for Being Cold Worked | Excellent | |

Capacity for Being Hot Formed | Excellent | |

Forgeability Rating | 65 | |

Machinability Rating | 20 |

Feel free to connect with us and get solutions and price quote in an instant.

Turkey, Singapore, Thailand, Philippines, Brazil, Greece, Italy, Egypt, Finland, Germany, Korea, Bahrain, USA, India, Spain, Poland, Netherlands, Romania, UK, Australia, UAE, South Africa, Malaysia, Canada, Russia, Mexico, Norway, Sweden, France, Saudi Arabia