- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

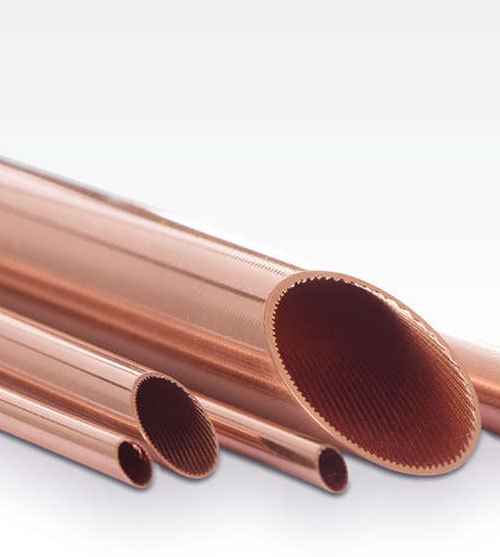

90/10 Copper Nickel Tube are used in ships, power plants, hydraulic lines and in offshore fire water systems. Its chemical composition is Nickel 10.5, Iron 1.5, Manganese 0.75 and the remainder is Copper. Because of its high ductility and toughness, 90/10 copper nickel tubing are very popular for use in industrial applications and architectural applications. The Ultimate Tensile Strength of Cu-Ni 90/10 Tube is 300 – 310 N/mm2. The 0.2% Proof Strength of 90/10 CU NI Tube is 105 N/mm2. The Elongation percentage of 90/10 copper nickel is 30.

Cupro Nickel 90 / 10 Seamless Tube offers superb resistance to erosion and stress corrosion and it also has excellent resistance to biofouling in brackish water and seawater. Cu-Ni 90 / 10 Tube (UNS C70600) also displays terrific welding and fabrication properties. Plus, to hydrogen embrittlement, Copper Nickel 90 / 10 Round Tube has a very high resistance. Related specifications of Cu-Ni 90/10 Tube are C70600, CW352H, DEF STAN 02-779, BS2874, CN102, NF A51-115, ASTM B151, C70610, EN 12163, DEF STAN 02-879 Annex C, 2.0872, NES 779, CuNi10Fe1Mn and BS2870. Cupro nickel 90/10 tube are also used in desalination units, fish cages for aquaculture, sea water pipe-work and in condensers and heat exchangers. Cu-Ni 90 / 10 Square Tube has excellent antimicrobial properties. Within just a matter of a couple of hours, it can kill a huge range of microbes, including the likes of influenza A (H1N1), Clostridium difficile, E. coli and MRSA. We are an ISO certified and oldest 90/10 Copper Nickel Tube Suppliers in Mumbai, India.

Copper Nickel 90/10 / C70600 Seamless Tube acc.to ASTM B111 or EN12451

Fixed Lengths: Diameter 9.52 to 60.00mm / Wall Thickness 0.6 to 3.0mm / Length 1 to 20.00 metres

In Coils: Diameter 4.76 to 22.22mm / Wall Thickness 0.6 to 1.20mm / Length Dependant on Diameter / Wall requested

90/10 CuNiFe Tube (BS2871 CN102) Kunifer 10 Metric and Imperial.

(Condenser & Heat exchanger, Hydraulic, Heating Coils & Grids and Instrumentation) Seamless and Seam welded Coils also available in smaller O/Ds.

| End Product | Specification |

|---|---|

| Condenser Tube | ASME SB171, ASTM B171, SAE J463, J461 |

| Tube, Condenser | ASME SB111, ASTM B552, B111, MILITARY MIL-T-15005, SAE J463, J461 |

| GRADES | 90/10 (COPPER/NICKEL), SB111 c70600 |

| Tube ASTM Standard | ASTM B111, B359, B466, B467, B469, B552, B543, B608 |

| FORM | SEAMLESS |

| TEMPER | ANNEALED (HARD DRAWN IF REQUIRED) |

| SMALLEST O/D | 0.020" |

| LARGEST O/D | 0.591" |

| WALL THICKNESS RANGE | 0.007" - 0.0118" |

| CUT RANGE | ANY LENGTH NO MATTER HOW SHORT |

| SUPPLIED IN | STRAIGHT LENGTHS OR COILS WHERE APPLICABLE |

| International specifications | ASME, SAE, MIL, QQ, ISO, BS, and JIS. |

|---|---|

| Coppernickel 90/10 Tube Standards | ASTM B 111, B543, B552 ASME SB 111, SB543, SB552 |

| Seamless Tube Size | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Wall thickness | 0.020" –0.220", (special wall thicknesses available) |

| Length | Single Random, Double Random, Standard & Cut length |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Form | Round, Coil, Square, Rectangular, Boiler, Hydraulic, Straight or ‘U’ bent Tube, Hollow, LSAW Tube Etc. |

| Type | Seamless, ERW, EFW, Welded, Fabricated |

| End | Plain End, Beveled End, Treaded |

| Marking | All 90/10 Copper Nickel tubes are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | Copper Nickel 90/10 Capillary Tube & Other Odd Size Copper Nickel 90/10 Heat Exchanger & Condenser Tube |

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| We can also cut, thread, and groove 90/10 Cupro Nickel Tube to meet your specifications | |

| Wall | Sizes ( O.D.) |

|---|---|

| .010 | 1/16" , 1/8" , 3/16" |

| .020 | 1/16" , 1/8" , 3/16" , 1/4" , 5/16" , 3/8" |

| .012 | 1/8" |

| .016 | 1/8" , 3/16" |

| .028 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 3/4" , 1" , 1 1/2" , 2" |

| .035 | 1/8" , 3/16" , 1/4" , 5/16" , 3/8" , 7/16" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .049 | 3/16" , 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/8" , 1 1/4" , 1 1/2" , 1 5/8" , 2" , 2 1/4" |

| .065 | 1/4" , 5/16" , 3/8" , 1/2" , 16" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 3/4" , 2" , 2 1/2" , 3" |

| .083 | 1/4" , 3/8" , 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 1 5/8" , 1 7/8" , 2" , 2 1/2" ,3" |

| .095 | 1/2" , 5/8" , 1" , 1 1/4" , 1 1/2" , 2" |

| .109 | 1/2" , 3/4" , 1" , 1 1/4" , 1 1/2" , 2" |

| .120 | 1/2" , 5/8" , 3/4" , 7/8" , 1" , 1 1/4" , 1 1/2" , 2" , 2 1/4" , 2 1/2" , 3" |

| .125 | 3/4" , 1" , 1 1/4" , 1 1/2" , 2" , 3" , 3 1/4" |

| .134 | 1" |

| .250 | 3" |

| .375 | 3 1/2" |

US $4.00-$4.50 / Meter

Above is an approx price, please contact for final price of Copper Nickel 90/10 Tube

| Cu-Ni 90/10 | Cu | Pb | Mn | Fe | Zn | Ni |

| 88.6 min | 0.05 max | 1.0 max | 1.8 max | 1 max | 9-11 max |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

|---|---|---|---|---|

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35,000, MPa – 241 | Psi -80,000, MPa -551 | 30 % |

| STANDARD | UNS | WERKSTOFF NR. |

|---|---|---|

| Cupro Nickel 90/10 | C70600 | 2.0872 |

88.35 Cu | 10.0 Ni | 0.40 Mn | 1.25 Fe | 20 Relative Machinability | "S" Weight Factor - 12.20

| Composition (Percent) | Copper (inc. Silver) 88.6, Lead .05 max., Iron 1.8 max., Zinc 1.0 max., Nickel 11.0 max., Manganese 1.0 max. |

| Nearest Applicable ASTM Specifications | B111, B359, B395, B466, B467, B543, B552 |

| Melting Point (Liquidus) | 2100 F |

| Cold Working Capacity | Good |

| Hot Forming Capacity | Good |

| Hot Forgeability Rating | n/a (Forging Brass = 100) |

| Hot Working Temperature | 1550 - 1750 F or 850 - 950 C |

| Annealing Temperature | 1100 - 1500 F or 600 - 825 C |

| Machinability Rating | 20 (Free Cutting Brass = 100) |

| Temper | Tensile Strength | Yield Strength * | Elongation in 2 in. | Rockwell Hardness (F) | Rockwell Hardness (B) | Rockwell Hardness (30T) | Shear Strength |

|---|---|---|---|---|---|---|---|

| .025 mm | 44.0 ksi | 16.0 ksi | 42 % | 65 | 15 | 26 | - |

| Light Drawn | 60.0 ksi | 57.0 | 10 % | 100 | 72 | 70 | - |

Drawn – General Purpose (H58)Temper is suitable to use for general purpose tube only, usually where there is no real requirement for high strength or hardness on the one hand or for bending qualities on the other.

Hard Drawn (H80)Temper is commonly used only when there is need for hard or strong tube as is commercially feasible for the size in question.

Light Drawn – Bending (H55)Temper is suitable only when a stiffness tube is required, but yet capable of readily being bent (or otherwise moderately cold worked) is needed.

Typical Uses: Condensers, distiller tubes, condenser plates, evaporator and heat exchanger tubes, ferrules, salt water piping.

KS D5301 JIS H3300 | C7060T |

| ASTM B111 | C70600 |

| ASTM B466 | C70600 |

| BS2871 {PART2} | CN102 |

| AS1752 | C70600 |

| DIN17664 | CuNi10Fe 1Mn |

| DIN 86019 WL2.1972 | CuNi10Fe 1.6Mn |

| EEMUA 144 | 7060X |

| MIL-T-16420K | 706 |

| EN12449 | CW352H |

| Form | Specific Sub-Form | Application | System | Standard | Description |

|---|---|---|---|---|---|

| Condenser & Heat Exchanger Tube with Integral Fins | Welded | ASTM | B956/B956M | WELDED COPPER AND COPPER-ALLOY CONDENSER AND HEAT EXCHANGER TUBES WITH INTEGRAL FINS | |

| Tube | Condenser Tube | ASME | SB111 | COPPER AND COPPER ALLOY SMLS CONDENSER TUBES & FERRULE STOCK | |

| Finned | ASME | SB359 | COPPER & COPPER ALLOY SMLS CONDENSER & HEAT EXCHANGER TUBES WITH INTEGRAL FINS | ||

| U-Bend | ASME | SB395 | U-BEND SMLS COPPER & COPPER ALLOY HEAT EXCHANGER & CONDENSER TUBE | ||

| SMLS | ASME | SB466 | SMLS COPPER NICKEL PIPE AND TUBE | ||

| Welded | ASME | SB543 | WELDED COPPER AND COPPER ALLOY TUBE | ||

| Condenser Tube | ASTM | B111/B111M | COPPER AND COPPER ALLOY SMLS CONDENSER TUBES AND FERRULE STOCK | ||

| Finned | ASTM | B359/B359M | COPPER AND COPPER-ALLOY SMLS CONDENSER AND HEAT EXCHANGER TUBES WITH INTEGRAL FINS | ||

| U-Bend | ASTM | B395/B395M | U-BEND SMLS COPPER AND COPPER ALLOY HEAT EXCHANGER AND CONDENSER TUBES | ||

| Seamless | ASTM | B466/B466M | SMLS COPPER NICKEL PIPE AND TUBE | ||

| Seamless | ASTM | B469 | SMLS COPPER ALLOY TUBES FOR PRESSURE APPLICATION | ||

| Welded | ASTM | B543/B543M | WELDED COPPER AND COPPER ALLOY HEAT EXCHANGER TUBE | ||

| Condenser Tube | ASTM | B552 | SMLS AND WELDED COPPER NICKEL TUBES FOR WATER DESALTING PLANTS | ||

| Condenser Tube | MILITARY | MIL-T-15005 | TUBES, COPPER NICKEL ALLOY CONDENSER AND HEAT EXCHANGER | ||

| Welded | MILITARY | MIL-T-16420 | TUBE, COPPER NICKEL ALLOY, SMLS AND WELDED | ||

| Seamless | MILITARY | MIL-T-16420 | TUBE, COPPER NICKEL ALLOY, SMLS AND WELDED | ||

| Finned | MILITARY | MIL-T-22214 | TUBE, CONDENSER AND HEAT EXCHANGER WITH INTEGRAL FINS | ||

| Condenser Tube | SAE | J461 | WROUGHT AND CAST COPPER ALLOYS | ||

| Condenser Tube | SAE | J463 | WROUGHT COPPER AND COPPER ALLOYS |

| Cupro Nickel 90/10 condenser coil | Cupro Nickel 90/10 Pancake Coils |

| Copper Nickel 90/10 Finned Tube | Cupro Nickel 90/10 Capillary Tube |

| 90/10 Copper Nickel ‘U’ Shaped tubing | 90/10 Copper Nickel Gas Tube |

| ASTM B111 Cupro Nickel 90/10 seamless tubing | ASME SB111 Cupro Nickel 90/10 Thin Wall tube |

| Copper Nickel 90/10 seamless tube | Cupro Nickel 90/10 Furnace Tube |

| Cuni 90/10 welded tubing | 90/10 Copper Nickel tubes |

| Cupro Nickel 90/10 Heat Exchanger Tube | Copper Nickel 90/10 boiler tube |

| 90/10 Copper Nickel Square Tube | Copper Nickel 90/10 Hydraulic tubes |

| Copper Nickel 90/10 Rectangle Tube | Cuni 90/10 tubing |

| Cupro Nickel 90/10 Seamless Tube | Cupro Nickel 90/10 Round Tube |

| ASTM B111 Cupro Nickel 90/10 Welded Tube | 90/10 Copper Nickel Seamless Tubing |

| 90/10 Copper Nickel Coiled Tubing | Copper Nickel 90/10 Capillary Tubing |

| Cupro Nickel 90/10 Aerospace tubes | Cuni 90/10 High Pressure Tube |

| Copper Nickel 90/10 Sighting Tube | Cupro Nickel 90/10 Polish Tube |

| 90/10 Copper Nickel Elliptical and Oval Tube | 90/10 Copper Nickel Rectangular Tube |

| Cupro Nickel 90/10 Condenser Tube | ASTM B111 Cupro Nickel 90/10 Aero engine tubes |

| SB111 Cupro Nickel 90/10 straight tube boiler | Cupro Nickel 90/10 furnace tube |

| Cuni 90/10 brake tubing | Cold Drawn Seamless tube |

| Copper Nickel 90/10 Extruded Seamless Tube | 90/10 Copper Nickel Precision tube |

| 90/10 Copper Nickel Tubing bends | Cuni 90/10 Capillary tube |

| Cupro Nickel 90/10 Gas Tube | Cupro Nickel 90/10 Fluid Tube |

| Copper Nickel 90/10 ERW Tube | Copper Nickel 90/10 EFW Tube |

| 90/10 Copper Nickel Round Tube | Cu-Ni 90/10 ERW Tube |

| ASTM B111 Copper Nickel 90/10 Tube | ASTM B552 Cupro Nickel 90/10 Square Tube (Radius Corners) |

| Cupro Nickel 90/10 Instrumentation Tube | ASTM B543 Cuni 90/10 protective tubes |

| Product Category | Product |

|---|---|

| Automotive | Brake Lines |

| Brake Lines | |

| Brake Lines | |

| Power Steering Tube | |

| Power Steering Tube | |

| Power Steering Tube | |

| Industrial | Condensers |

| Condensers | |

| Condensers | |

| Condensers | |

| Condensers | |

| Distiller Tube | |

| Distiller Tube | |

| Distiller Tube | |

| Distiller Tube | |

| Distiller Tube | |

| Evaporator Tube | |

| Evaporator Tube | |

| Evaporator Tube | |

| Evaporator Tube | |

| Evaporator Tube | |

| Evaporators | |

| Evaporators | |

| Evaporators | |

| Ferrules | |

| Ferrules | |

| Ferrules | |

| Ferrules | |

| Ferrules | |

| Heat Exchanger Tubes | |

| Heat Exchanger Tubes | |

| Heat Exchanger Tubes | |

| Heat Exchanger Tubes | |

| Heat Exchanger Tubes |

| Country | Days | Country | Days |

|---|---|---|---|

| USA | 45 | Canada | 45 |

| Australia | 30 | UK | 35 |

| Malaysia | 15 | Poland | 15 |

| Iran | 7 | Singapore | 14 |

| Vietnam | 20 | Albania | 20 |

| UAE | 15 | Thailand | 20 |

| Nigeria | 40 | Ethiopia | 40 |

| Turkey | 30 | Tanzania | 30 |

| Bahrain | 15 | Kenya | 40 |

| Libya | 40 | Syria | 40 |

| Zambia | 40 | Egypt | 40 |

| Italy | 40 | India | 7 |

| Saudi Arabia | 15 | Qatar | 15 |

| Namibia | 40 | Indonesia | 20 |

| South Africa | 40 | Australia | 40 |

| Uganda | 40 | Angola | 40 |

| Kazakhstan | 20 | Algeria | 20 |

Feel free to connect with us and get solutions and price quote in an instant.

Turkey, Singapore, Thailand, Philippines, Brazil, Greece, Italy, Egypt, Finland, Germany, Korea, Bahrain, USA, India, Spain, Poland, Netherlands, Romania, UK, Australia, UAE, South Africa, Malaysia, Canada, Russia, Mexico, Norway, Sweden, France, Saudi Arabia