- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

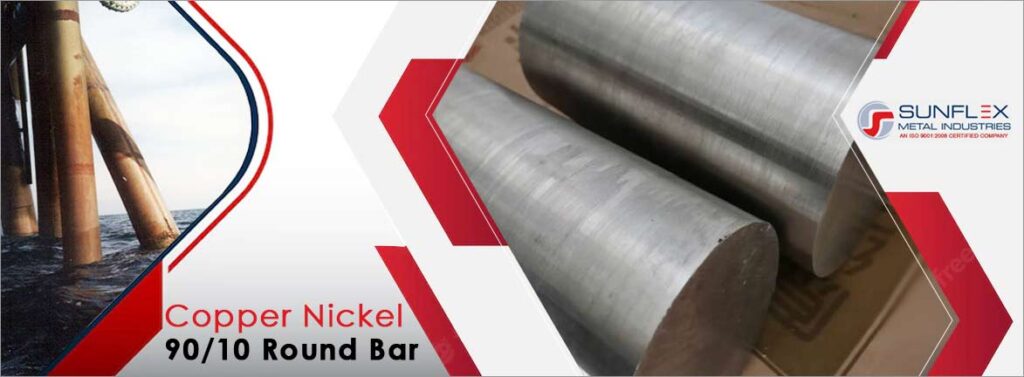

If you ask what is Copper Nickel 90/10 Round Bar, then they are round shaped bars made of austenitic alloy that comprises 90% copper, 10% nickel, along with other components like manganese and iron. The ASTM B151 C70600 material is known for showing high resistance to the acidic environments, especially sulphuric acid, which is the most lethal. The Copper Nickel 90/10 Rod is also known for its excellent resistance to corrosion, which includes both pitting and crevice corrosion. The ASTM B151 UNS C70600 material is able to retain its properties even in the presence of chemicals containing chlorides.

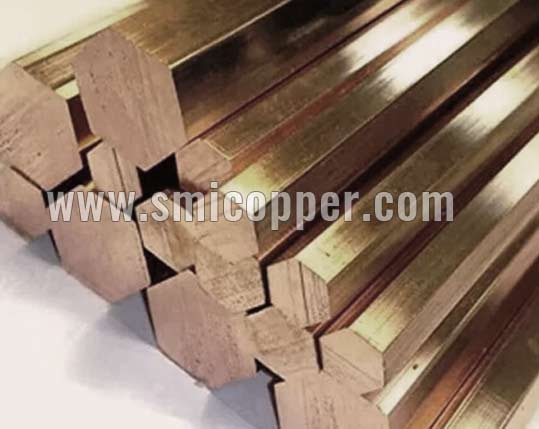

The chemical composition of the CuNi 90/10 Hex Bar is such that it shows great flexibility even in hot working conditions, provided they are applied correctly. It is due to the strength of the Copper Nickel 90/10 Rod that they do not get damaged quite easily, even if it gets exposed to a temperature above 1200 degrees F and that too for a long period of time. The ASTM B151 UNS C70600 Flat Bar is highly demanded due to its properties and long-lasting service life. In other words, it can be said that the UNS C70600 Forged Bar has a perfect blend of enhanced mechanical properties, with corrosion resistance, and high fabricability. However, it is to be noted that the ASTM B151 GR. C71500 products are subjected to crevice corrosion and pitting when they get exposed to warm chloride environments.

It is also easy to customize the ASTM B151 C70600 Square Bar in desired size and dimensions. Their shapes can also be customized and they can be given desirable surface appearance. For example, the CuNi 90/10 Bright Bar comes with a shiny surface appearance and thus, they can be used in places that are highly visible.

All the above properties and features make the CuNi 90/10 Cold Drawn Bar highly applicable in industries such as petrochemical, energy, chemical, power plant, food processing, oil and gas, etc.

90/10 Copper Nickel Bar offers superb corrosion resistance, even in an environment such as marine salt water. Cupro Nickel 90/10 Round Bar has a Density of 0.323 lb/in³ (8.94 g/cm3). The Elongation at Break of 90/10 Cu-Ni Rods (rolled-H04 for flat products/hard drawn-H80 for tubing), is 11.00% and its Elongation at Break (annealed), is 40%. The Poisson’s Ratio of UNS C70600 Hex Bar (C71500 annealed) is 0.325. Copper Nickel 90/10 Round Bar contains nickel and copper and strengthening elements like manganese and iron. These bars of copper nickel are used a lot in ammunition, condenser tubes, cooling circuits, sea water corrosion-resistant assemblies, etc.

Cu-Ni 90/10 Bright Bar properties are that of 90% copper and 10% nickel alloy and to increase the corrosion resistance, manganese and iron are added to it. It has a Tensile Strength (annealed) of 52000 psi (359 MPa) and it has a Tensile Strength (rolled-H04 for flat products/ hard drawn-H80 for tubing) of 78000 psi (538 MPa). The Chemical Composition is Cu Bus Bar is 71.25-76.5, Fe ≤ 0.20, Pb ≤0.050, Mn ≤ 1.0, Ni 23.5-26.5 and Zn ≤ 1.0. ASTM B151 Cupro Nickel 90/10 Forged Bars has properties that display high resistance to bio-fouling and seawater corrosion. Because of their resistance to biofouling, round bars of copper nickel find use in various application areas involving seawater intake screens, oil rigs and platforms, chemical and marine environments of boat and ship hulls, seawater and hydraulic platforms, heat exchange equipment, fish farming cages and desalination plants. As there is no need for surface protection by 90/10 and due to the fact that it delivers extra safety, Cu-Ni DIN 2.0872 Square Bar is now being used in cooling systems and in hydraulic and brake suspension systems in commercial vehicles and cars.

| Standard Specifications Met | Marine-Grade, ASTM B151, ASME SB151, UNS C70600, DIN 2.0872, NACE-MR0175, MILITARY MIL-C-15726, ISO-15156 |

| Manufacturing type |

|

| Copper Nickel 90/10 Round Bar sizes | 6 mm to 120 mm 1/2" to 24" |

| 9010 Copper Nickel Square Bar | 10 mm to 200 mm |

| ASTM B151 UNS C70600 Solid Bar | 1/4" - 12" diameter |

| UNS C70600Bar Length | 100 mm to 3660 mm Long |

| Condition of CuNi 90/10 Bar stock | Cold Drawnd Pulished, Annealed, and Cold Drawn Centreless Ground & Polished ASTM B151 C70600 material |

| Manufacturing Technique | Cold Drawn, , Copper Nickel 90/10 Hot Rolled, Cold Rolled, Forged Round Bar, and ASTM B151 C70600 Rod |

| Tolerance | H13, K9, H12, H11, H9, K10, K12, H8, H10, K11 |

| Yield Strength | 110,000 psi |

| Hardness | Rockwell C30 (Hard) |

| Temper | AT110 (Hard) |

| Heat Treatable | No |

| Material Test Certificates (MTC) | All Copper Nickel 90/10 Round Bar material supplied with MTC EN 10204 3.1, 3.2 |

| Manufacturing Type | Manufacturing Size | Price List in India |

|---|---|---|

| ASTM B466 COPPER NICKEL ROUND BAR | 40MM * Length 2 MTR | FOB Price: US $ 345 - US $ 348 per Pcs |

| 90/10 COPPER NICKEL ROD | OD 150 mm * Length 0.78 MTR | FOB Price: US $ 1000 - US $ 1080 per MTR |

| COPPER NICKEL 90/10 ROD | OD 85 mm * Length 0.50 MTR | FOB Price: US $ 300 - US $ 350 per MTR |

| COPPER NICKEL 90/10 ROUND BAR Price per kg in India | - | FOB Price: US $ 5 - US $ 6 per Kg |

| CU-NI 90/10 Bar, ASTM B171 C70620 | OD 20mm * Length 2.5 MTR | FOB Price: US $ 135 - US $ 140 per Pcs |

| Shape | Bore Size |

|---|---|

| Copper Nickel 90/10 Hollow Rods | 20 mm min and OD 100 mm max |

| 9010 Copper Nickel Round Rods | 8 To 100 mm |

| ASTM B151 UNS C70600 Hex Bar | 10 To 60mm |

| UNS C70600 Square Bar | 10 To 60mm |

| CuNi 90/10 Flat Bar | Min 10mm Thickness and Width 120mm max |

| Cupro Nickel 90/10 Billets | Up to 200 mm |

| 9010 Cupro Nickel Ingots | As per Client's specification |

| Copper Nickel 90/10 Round Bar | |

|---|---|

| Metric Size | 6.35 mm to 88.9 mm |

| Imperial Size | 0.25 in to 3.5 in |

| 9010 Copper Nickel Square Bar | |

| Metric Size | 6.35 mm to 35 mm |

| Imperial Size | 0.25 in to 1.25 in |

| ASTM B151 UNS C70600 Flat Bar | |

| Metric Size | 15 mm to 35 mm x |

| Imperial Size | 4 mm to 12.7 mm |

| UNS C70600 Hex Bar | |

| Metric Size | 6.35 mm to 69.85 mm A/F |

| Imperial Size | 0.25 in to 2.75 in |

| Copper Nickel 90/10 Round Bar | |

|---|---|

| Metric Size | 20 mm to 450 mm |

| Imperial Size | 0.75 in to 17.7165 in |

| 9010 Copper Nickel Square Bar | |

| Metric Size | 20 mm to 450 mm |

| Imperial Size | 0.75 in to 17.7165 in |

| ASTM B151 UNS C70600 Flat Bar | |

| Metric Size | 0.5905 in to 1.3779 in x |

| Imperial Size | 0.1574 in to 0.5 in |

| Squares | |

|---|---|

| C mm |

Theoretical weight Kg/m |

| 20 x 20 mm | 3.57 |

| 30 x 30 mm | 8.05 |

| 40 x 40 mm | 14.26 |

| 50 x 50 mm | 22.35 |

| 60 x 60 mm | 32.25 |

| 70 x 70 mm | 43.80 |

| 80 x 80 mm | 57.16 |

| 90 x 90 mm | 72.44 |

| 100 x 100 mm | 89.50 |

| 10 x 10 mm | 0.90 |

| Copper Nickel 90/10 Round Rod | Copper Nickel 90/10 Hexagonal Bar | Copper Nickel 90/10 Square Bar | Copper Nickel 90/10 Flat Bar | ||||

|---|---|---|---|---|---|---|---|

| D mm |

Theoretical weight Kg/m | H mm |

Theoretical weight Kg/m | C mm |

Theoretical weight Kg/m | L x I mm | Theoretical weight Kg/m |

| 10 | 0.70 | 12 | 1.11 | 10 x 10 | 0.90 | 20 x 10 | 1.70 |

| 15 | 1.58 | 14 | 1.51 | 20 x 20 | 3.57 | 30 x 10 | 2.67 |

| 20 | 2.80 | 17 | 2.27 | 30 x 30 | 8.05 | 40 x 10 | 3.57 |

| 25 | 4.39 | 19 | 2.78 | 40 x 40 | 14.26 | 40 x 20 | 7.13 |

| 30 | 6.32 | 22 | 3.73 | 50 x 50 | 22.35 | 45 x 30 | 12.05 |

| 35 | 8.60 | 24 | 4.43 | 60 x 60 | 32.25 | 50 x 20 | 8.90 |

| 40 | 11.20 | 27 | 5.64 | 70 x 70 | 43.80 | 60 x 20 | 10.75 |

| 45 | 14.20 | 30 | 6.97 | 80 x 80 | 57.16 | 60 x 30 | 16.13 |

| 50 | 17.55 | 32 | 7.92 | 90 x 90 | 72.44 | 60 x 40 | 21.90 |

| 55 | 21.20 | 36 | 9.96 | 100 x 100 | 89.50 | 80 x 20 | 14.30 |

| 60 | 25.30 | 37 | 10.77 | 80 x 40 | 28.57 | ||

| 65 | 29.70 | 38 | 11.13 | 90 x 30 | 24.15 | ||

| 70 | 34.40 | 40 | 12.35 | 90 x 60 | 48.30 | ||

| 75 | 39.40 | 41 | 12.98 | 100 x 50 | 44.75 | ||

| 80 | 44.90 | 42 | 13.59 | 100 x 70 | 62.45 | ||

| 85 | 50.70 | 46 | 16.30 | 120 x 30 | 32.12 | ||

| 90 | 56.90 | 50 | 19.36 | 120 x 40 | 42.82 | ||

| 95 | 63.10 | 55 | 23.40 | 120 x 60 | 64.23 | ||

| 100 | 69.87 | 60 | 27.90 | 120 x 80 | 85.65 | ||

| 105 | 77.03 | 65 | 32.60 | ||||

| 110 | 84.54 | 70 | 38.55 | ||||

| 115 | 92.40 | 75 | 44.25 | ||||

| 120 | 100.61 | 80 | 49.53 | ||||

| 125 | 109.00 | 85 | 55.93 | ||||

| 130 | 118.00 | ||||||

| 140 | 136.00 | ||||||

| 150 | 157.00 | ||||||

| 160 | 179.00 | ||||||

| 170 | 206.00 | ||||||

| 180 | 228.00 | ||||||

| 190 | 257.50 | ||||||

| 200 | 280.00 | ||||||

| 250 | 445.80 | ||||||

| 285 | 570.50 | ||||||

| GAM MM11/ GAM MM13 (French Navy) | DIN 17664 / Alloy 2.0872 | BS 2872 Alloy CN 102-O | ASTM B151 UNS C70600 |

| FRANCE | GERMANY | UNITED KINGDOM | U.S.A |

|---|

| Element Alloy | Cupronickel 90/10 Bar Stock |

|---|---|

| Copper (Cu) | 88.6 |

| Manganese | 1.0 |

| Lead | 0.05 |

| Iron | 1.8 |

| Nickel (Ni) | 9-11 |

| Zinc | 1.0 |

COMMERCIAL

| UNS No. | Copper + Silver | Carbon | Phosphorus | Manganese | Lead | Nickel + Cobalt | Sulfur | Iron | Zinc |

|---|---|---|---|---|---|---|---|---|---|

| C71500 | remainder | 1.0 max | 0.05a max | 29.0-33.0 | 0.40-1.0 | 1.0a | |||

| C71520 | 65.0 min | 0.05 max | 0.02 max | 1.0 max | 0.02 | 29.0-33.0 | 0.02 max | 0.40-1.0 | 0.5 |

| UNS No. | Copper + Silver | Carbon | Phosphorus | Manganese | Lead | Nickel + Cobalt | Sulfur | Iron | Zinc |

|---|---|---|---|---|---|---|---|---|---|

| C71500 | remainder | 1.0 max | 0.05a max | 29.0-33.0 | 0.40-1.0 | 1.0a | |||

| C71520 | 65.0 min | 0.05 max | 0.02 max | 1.0 max | 0.02 | 29.0-33.0 | 0.02 max | 0.40-1.0 | 0.5 |

| UNS No. | Copper | Nickel + Cobalt | Lead | Manganese | Phosphorus | Iron | Carbon | Zinc | Sulfur | Cu + plus elements with specific limits, min |

|---|---|---|---|---|---|---|---|---|---|---|

| C71500 | 65.0 min | 29.0-33.0 | 0.02 max | 1.0 max | 0.02 max | 0.40-1.0 | 0.05 max | 0.50 max | 0.02 max | 99.5 |

| UNS No. | Nickel + Cobalt | Copper + Silver | Manganese | Zinc | Lead | Phosphorus | Iron | Carbon | Sulfur | Cu + plus elements with specific limits, min |

|---|---|---|---|---|---|---|---|---|---|---|

| C71500 | 29.0-33.0 | 65.0 min | 1.0 max | 0.50 max | 0.02 max | 0.02 max | 0.40-1.0 | 0.05 max | 0.02 max | 99.5 |

| UNS No. | Phosphorus | Iron | Copper + Silver | Zinc | Manganese | Lead | Nickel + Cobalt | Carbon | Sulfur |

|---|---|---|---|---|---|---|---|---|---|

| C71500 | 0.02 max | 0.40-1.0 | remainder | 0.50 max | 1.0 max | 0.02 max | 29.0-33.0 | 0.05 max | 0.02 max |

| Density @ 68° F | 0.323 lb/in3 |

| Melting Range | 2140-2265o F |

| Hot Formability | Good |

| Cold Formability | Good |

| Machinability rating (C360 = 100) | 20 |

| Brazing | Excellent |

| Soldering | Excellent |

| Gas-shielded arc welding | Excellent |

| Oxy-acetylene welding | Good |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Good |

| Resistant welding: spot and seam | Good |

| Resistance Welding: butt | Good |

Feel free to connect with us and get solutions and price quote in an instant.