- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

If you are wondering what is Copper Nickel 90/10 Pipe, then it can be defined as a pipe that has 90% copper and 10% nickel in its alloy. Other than that, the chemical composition of the CuNi 90/10 Pipe also consists of iron and manganese, which enhances the overall strength and corrosion resisting capabilities of the pipe. The 90/10 Copper Nickel Pipe comes with high ductility and toughness, which is why they are a popular grade for different marine and industrial applications. Due to the high toughness, the ASTM B466 UNS C70600 material is also used in several architectural applications.

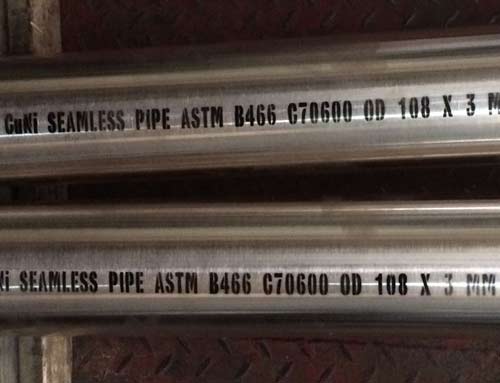

The UNS C70600 Pipe possesses some good mechanical properties, which includes good resistance to stress corrosion cracking. They can also effectively resist erosion and biofouling in the seawater environment. The Copper Nickel Pipe 90/10 comes with excellent fabricability and they have good welding properties too. They have high resistance to hydrogen embrittlement. One of the best things about the MIL-T-16420K alloy 706 Round Pipe is that they can retain their properties down to the cryogenic temperatures. The CuNi 90/10 Seamless Pipe is more reliable and less prone to leakage compared to the welded pipes due to the absence of seams. This is why they are used for more critical applications, but they are more expensive than the CuNi 90/10 Welded Pipe too.

Due to all the above properties, pipes and other products made with the ASME SB 466 UNS C70600 material are used for a wide range of applications. This would include equipment in the following industries:

The 90/10 Pipe has great antimicrobial properties and that is why they are in high demand in the application areas related to hygiene and sanitary environments, like hospitals, kitchens, and various healthcare environments.

Cu-Ni 90/10 Pipe properties are that they exhibit tremendous resistance to corrosion by sea water, because of the significant quantity of iron and manganese that are present in them. The Elongation at Break of 90/10 Cu-Ni Seamless Pipes (rolled-H04 for flat products/hard drawn-H80 for tubing), is 11.00% and its Elongation at Break (annealed), is 40%. The Molecular Formula of ASME SB466 Cupro Nickel Pipe is CuNi. Copper nickel 90/10 fuel pipe has a Density of 0.323 lb/in³ (8.94 g/cm3). 90/10 Copper Nickel Pipe has superb antimicrobial properties. As an oldest 90/10 Copper Nickel Pipe suppliers in Mumbai SMI copper offers excellent scaling resistance CuNi 90/10 Pipe which has very good hot and cold workability. 90/10 copper nickel alloy pipe has a small temperature coefficient of electrical resistance.

UNS C70600 Welded Pipe has big demand in various applications such as heat exchanger bases and plates, electrical resistors, oil coolers, condenser tubes, air conditioning plants, heating cables, seawater desalination plants, anodes for TV tubes and light-current switches. Cu-Ni 90/10 Seamless Pipes chemical composition is that of Cu 71.25-76.5, Fe ≤ 0.20, Pb ≤0.050, Mn ≤ 1.0, Ni 23.5-26.5 and Zn ≤ 1.0. The Yield Strength (annealed) of Copper nickel is B466 C70600 Pipe 15000 psi (103 MPa). UNS C70600 Pipe has a Rockwell B Hardness of 69. Cupro Nickel DIN 2.0872 Welded Piping is solderable and it has low electrical resistivity. ASTM B466 Cupro Nickel 90/10 Seamless Pipes has excellent welding and fabrication properties. Copper Nickel 90/10 brake pipe is used in low heating temperature heating cables, plug connectors, electrical resistors, power stations, measurement resistors, finned tubes, dynamo slip rings, control and load resistors and in the chemical industry.

| Outside Diameter | Wall Thickness Chart | THEORETICAL WEIGHT | |||

|---|---|---|---|---|---|

| Nominal Size (inch) | Actual Size ( mm) |

Actual WT (mm) |

Actual WT (inch) |

Kg/m | Lb/Ft |

| Copper Nickel 90/10 Seamless Pipes | |||||

| 1/8 | 10,29 | 1,47 | 0,058 | 0,36 | 0,24 |

| 1/4 | 13,72 | 1,65 | 0,065 | 0,56 | 0,38 |

| 3/8 | 17,15 | 1,65 | 0,065 | 0,72 | 0,48 |

| 1/2 | 21,34 | 1,65 | 0,065 | 0,91 | 0,61 |

| 3/4 | 26,67 | 1,65 | 0,065 | 1,16 | 0,78 |

| 1 | 33,4 | 1,65 | 0,065 | 1,47 | 0,99 |

| 1 1/4 | 42,16 | 1,83 | 0,72 | 2,07 | 1,39 |

| 1 1/2 | 48,26 | 1,83 | 0,72 | 2,39 | 1,60 |

| 2 | 60,32 | 2,11 | 0,083 | 3,45 | 2,32 |

| 2 1/2 | 73,03 | 2,11 | 0,083 | 4,20 | 2,82 |

| 3 | 88,9 | 2,41 | 0,095 | 5,85 | 3,93 |

| 3 1/2 | 101,6 | 2,41 | 0,095 | 6,71 | 4,51 |

| 4 | 114,3 | 2,77 | 0,109 | 8,68 | 5,83 |

| 5 | 141,3 | 3,18 | 0,125 | 12,34 | 8,29 |

| 6 | 168,3 | 3,4 | 0,134 | 15,75 | 10,58 |

| 8 | 219,1 | 3,4 | 0,134 | 20,60 | 13,84 |

| 9010 Copper Nickel Seamless Pipes OR ASTM B466 UNS C70600 Welded Pipes | |||||

| 10 | 273,05 | 3,4 | 0,134 | 25,75 | 17,30 |

| 12 | 323,9 | 3,96 | 0,156 | 35,58 | 23,91 |

| 14 | 355,6 | 4,19 | 0,165 | 41,35 | 27,79 |

| 16 | 406,4 | 4,19 | 0,165 | 47,33 | 31,81 |

| 18 | 457 | 4,57 | 0,18 | 58,07 | 39,02 |

| 20 | 508 | 4,57 | 0,18 | 64,62 | 43,42 |

| UNS C70600 Welded Pipes | |||||

| 24 | 610 | 4,57 | 0,18 | 77,71 | 52,22 |

| 30 | 762 | 6,35 | 0,25 | 134,77 | 90,56 |

| Specific Sub-Form | System | Standard | Description |

|---|---|---|---|

| Seamless | ASME | SB 466 / SB 466M | CuNi 90/10 Seamless Pipes |

| Welded | ASME | SB 467/ SB 467M | CuNi 90/10 Welded Pipes |

| Seamless | ASTM | B466/ B466M | CuNi 90/10 Seamless Pipes |

| Welded | ASTM | B467/ B467M | CuNi 90/10 Welded Pipes |

| Supplier of | Size Range | Price List |

| ASTM B466 UNS C70600, Copper Nickel 90/10 Pipes, Seamless | 1.5 MTR LONG | FOB Price: US $ 135 - US $ 136 per piece |

| Copper Nickel 90/10 Pipes | 7MM O.D * 0.5MM | FOB Price: US $ 13 - US $ 14 per kg |

| 90/10 Copper Nickel Pipes | 16 MM OD * 1.0 MM, 2880mm long | FOB Price: US $ 8 - US $ 9 per piece |

| Annealed UNS C70600 Pipes | FOB Price: US $ 910 - US $ 940 per meter | |

| Annealed, Copper Nickel 90/10 Seamless Pipes | NPS 1 1/2 , 3.81 Thick, 12 TO 20 feet long | FOB Price: US $ 80 - US $ 82 per meter |

| Outside Diameter (OD) | Cuni 90/10 Pipes | |||||

| Pressure: 20 bar UNS C70600 Pipes | Pressure: 16 bar UNS C70600 Pipes | |||||

| OD | Pipes Wall | Theoretical | Pipes Wall | Theoretical | ||

| thickness | Weight | thickness | Weight | |||

| Imperial Nominal | Metric Actual | |||||

| inch | DN | mm | mm | Kg/m | mm | Kg/m |

| 1/8 | 10 | 1 | 0.26 | 1 | 0.26 | |

| 1/4 | 12 | 1 | 0.31 | 1 | 0.31 | |

| 3/8 | 10 | 16 | 2 | 0.79 | 2 | 0.79 |

| 1/2 | 15 | 20 | 2 | 1.01 | 2 | 1.01 |

| 3/4 | 20 | 25 | 2 | 1.3 | 2 | 1.3 |

| 1 | 25 | 30 | 2.5 | 1.93 | 2.5 | 1.93 |

| 1 1/4 | 32 | 38 | 2.5 | 2.5 | 2.5 | 2.5 |

| 1 1/2 | 40 | 44.5 | 2.5 | 2.95 | 2.5 | 2.95 |

| 2 | 50 | 57 | 2.5 | 3.83 | 2.5 | 3.83 |

| 2 1/2 | 65 | 76.1 | 2.5 | 5.17 | 2.5 | 5.17 |

| 3 | 80 | 88.9 | 2.5 | 6.07 | 2.5 | 6.07 |

| 4 | 100 | 108 | 3 | 8.85 | 3 | 8.85 |

| 5 | 125 | 133 | 3 | 10.95 | 3 | 10.95 |

| 6 | 150 | 159 | 3.5 | 15.29 | 3 | 13.14 |

| 7 | 175 | 193.7 | 3.5 | 18.7 | 3 | 16.07 |

| 8 | 200 | 219.1 | 4.5 | 27.12 | 4 | 24.17 |

| 10 | 250 | 267 | 5.5 | 40.39 | 4.5 | 33.18 |

| 12 | 300 | 323.9 | 7 | 62.3 | 5.5 | 49.18 |

| 14 | 350 | 368 | 8 | 80.89 | 6.5 | 65.99 |

| 16 | 400 | 419.1 | 9 | 103.64 | 7 | 81 |

| 18 | 450 | 457.2 | 9.5 | 119.45 | 8 | 100.93 |

| 20 | 500 | 508 | 11 | 153.54 | 8.5 | 119.24 |

| 24 | 600 | 610 | 13 | 217.97 | 10.5 | 176.79 |

| 28 | 700 | 711 | 15 | 293.22 | 12 | 235.58 |

| 32 | 800 | 813 | 17 | 380.06 | 13.5 | 303.14 |

| 36 | 900 | 914 | 19 | 477.6 | 15.5 | 391.14 |

| Diameter of Copper Nickel 90/10 Pipes | 9010 Copper Nickel Pipes Tolerances Inch (mm) |

|---|---|

| Over 2 to 3 Inch (50.8 to 76.2 mm), incl | 0.005 (0.13) |

| Over 3 to 4 Inch (76.2 to 102mm), incl | 0.006 (0.15) |

| Over 4 to 5 Inch (102 to 127mm), incl | 0.008 (0.20) |

| Over 5 to 6 Inch (127 to 152mm), incl | 0.009 (0.23) |

| Over 6 to 8 Inch (152 to 203mm), incl | 0.010 (0.25) |

| Over 8 to 10 Inch (203 to 254mm), incl | 0.013 (0.33) |

| Over 10 to 12 Inch (254 to 305mm), incl | 0.015 (0.38) |

| Over 12 Inch (305 mm) | 0.5 % |

| BS 2871 CN 102 |

ASTM B466 C70600 |

MIL-T-16420K C70600 |

DIN 86019 CuNi10Fe1.6Mn 2.1972 |

EEMUA 234 UNS 7060X |

JIS H 3300 C7060 |

|

| Ni% | 10.0-11.0 | 9.0-11.0 | 9.0-11.0 | 9.0-11.0 | 10.0-11.0 | 9.0-11.0 |

| Fe% | 1.0-2.0 | 1.0-1.8 | 1.0-1.8 | 1.5-1.8 | 1.5-2.0 | 1.0-1.8 |

| Mn% | 0.5-1.0 | Max.1.0 | Max1.0 | 0.5-1.0 | 0.5-1.0 | 0.2-1.0 |

| C% | Max.0.05 | Max.0.05 | Max.0.05 | Max.0.05 | Max.0.05 | |

| Pb% | Max.0.01 | Max.0.02 | Max.0.02 | Max.0.03 | Max.0.01 | Max.0.05 |

| S% | Max.0.05 | Max.0.02 | Max.0.02 | Max.0.015 | Max.0.02 | |

| P% | Max.0.02 | Max.0.02 | Max.0.02 | Max.0.02 | ||

| Zn% | Max.0.50 | Max.0.05 | Max.0.15 | Max.0.20 | Max.0.50 | |

| Zr% | Max.0.03 | |||||

| Others | Max.0.30 | Max.0.30 | Max.0.30 | |||

| Cu% | Balance | Balance | Min.86.5 | Balance | Balance | Cu+Ni +Fe+Mn Min.99.5 |

| 16 bar/ 232 psi Copper Nickel 90/10 Pipes | 20 bar/ 290 psi 9010 Copper Nickel Pipes |

|---|---|

| -29°C/-20°F up to +75°C/+167°F |

-29°C/-20°F up to +38°C/+100°F |

| ASTM B466 C70600 Pipes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu% | Fe% | Ni% | C% | Mn% | S% | Pb% | Zn% | P% | Other imp. |

| Balance | 1.0-1.8 | 9.0-11.0 | max 0.05 | max 1.0 | max 0.02 | max 0.02 | max 0.50 | max 0.02 | - |

| DIN 86019 2.1972 Pipes ( CuNi10Fe1.6Mn) | |||||||||

| Cu% | Fe% | Ni% | C% | Mn% | S% | Pb% | Zn% | P% | Other |

| rem. | 1.5-1.8 | 9.0-11.0 | max. 0.05 | 0.5-1.0 | max. 0.005 | max. 0.01 | max. 0.05 | max. 0.02 | - |

| Values | CuNi 90/10 |

|---|---|

| Density (20°C) | 8900 kg/m3 |

| Electrical Resistivity (annealed 20°C) | 19 μΩ.cm |

| Thermal Conductivity (20°C - 200°C) | 50 W/m.°K |

| Coefficient of Expansion (20°C - 200°C) | 17 C x 10-6 |

| Modulus of Elasticity (annealed 20°C) | 126 000 Mpa |

| Annealing Temperature | 760 – 800 °C |

| Melting Interval | 1100 - 1150 °C |

| Magnetic Permeability (annealed 20°C) | 1.08 - 1.80 |

KS D5301 JIS H3300 |

C7060T |

| ASTM B111 | C70600 |

| ASTM B466 | C70600 |

| BS2871 {PART2} | CN102 |

| AS1752 | C70600 |

| DIN17664 | CuNi10Fe 1Mn |

| DIN 86019 WL2.1972 | CuNi10Fe 1.6Mn |

| EEMUA 144 | 7060X |

| MIL-T-16420K | 706 |

| EN12449 | CW352H |

Feel free to connect with us and get solutions and price quote in an instant.

Turkey, Singapore, Thailand, Philippines, Brazil, Greece, Italy, Egypt, Finland, Germany, Korea, Bahrain, USA, India, Spain, Poland, Netherlands, Romania, UK, Australia, UAE, South Africa, Malaysia, Canada, Russia, Mexico, Norway, Sweden, France, Saudi Arabia