- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

70/30 Copper Nickel Bar are capable of sustaining very high pressures. The Elongation at Break of Copper Nickel 70/30 Round Bar is 45.0% and its Shear Modulus is 8270 ksi (57.0 GPa). 70/30 Cu-Ni Rods has an Ultimate Tensile Strength of 54000-75000 psi (372-517 MPa) and it has a Yield Tensile Strength of 12800-70100 psi (88.0-483 MPa). UNS C71500 Hex Bar thermal conductivity is 29 W/m°K. The Elastic Modulus of 70 30 Cu Ni round bar is 21800 ksi (150 GPa) and its Poisson’s Ratio is 0.34. ASTM B151 Cupro Nickel 70/30 Forged Bars can be welded by using various welding processes such as seam welding, coated metal arc welding, gas shielded arc welding, brazing, oxyacetylene welding, soldering, butt welding and spot welding.

Cu-Ni 70/30 Bright Bar is ductile and strong and it offers superb resistance to erosion and corrosion. It is possible to anneal Cu-Ni DIN 2.0882 Square Bar at temperatures ranging between 1200 and 1500 °F (649 and 816 °C). 70 30 Cu Ni has an excellent cold working capacity and it can be hot formed in an excellent way. Cupro Nickel 70/30 Round Bar are used in various applications all over the world in machine tools, fasteners, machined components, medical parts, marine industries, pump shafts and valves. 70/30 Cupro Nickel Bars are used in various application processes such as fish cages for aquaculture, offshore fire water systems, desalination units, sea water pipe-work, tubes for ships and power plants, hydraulic lines, heat exchangers, condensers and in fasteners, valves, sheathings and pumps of ship hulls.

| Specifications | ASTM B151, ASME SB151, UNS C71500, DIN 2.0882 |

| Standards | MIL-C-15726F, ASTM B 151, Tempers 060 Soft & H01 Hard |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Range | 5 mm To 500 mm thick in 100 mm TO 6000 mm |

| Cu-Ni 70/30 Round Bars | 6 mm to 120 mm. |

| Cu-Ni 70/30 Square Bars | 10 mm to 200 mm. |

| Cupro Nickel 70/30 Solid Bar | 1/4" - 12" diameter |

| Range | 10 mm To 150 mm Dia in 100 mm TO 1000 mm Length |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 100 mm to 3660 mm Long |

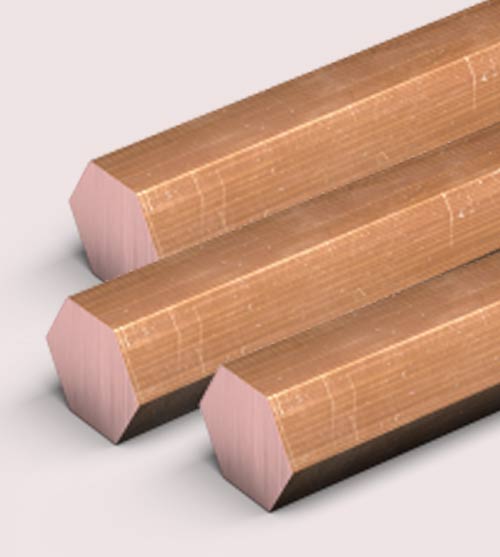

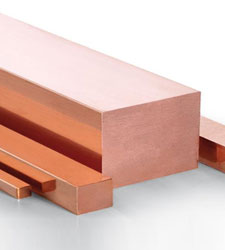

| Form | Round, Rod, Precision Ground Bar, Square, Round Rod, Hollow, Hex (A/F), Triangle, Rectangle, Threaded, T-Bar, Half Round Bar, Flat Bar, Rings, Blocks, Billet, Ingot, I/H Bar, Angle, Channel Bar, Profiles, Forging Etc. |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished, Annealed round bar |

| Technique | Copper Nickel 70/30 Hot Rolled, Cold Rolled, Cold Drawn, Forged Round Bar, Rod |

| Test Certificate | Mill Test Certificate as per EN 10204 / 3.1, NACE MR0175/ISO 15156 |

| ASTM | ASME | Military | |

|---|---|---|---|

| Bar | ASTM B151 ASTM B122 | ASME SB-151 ASME SB-122 | MIL-C-15726 |

Fittings

Flanges

Fasteners

Marine hardware

Condenser taper tube plugs

| ASTM | ASME | Military | |

|---|---|---|---|

| Cupro Nickel 70/30 Rod | ASTM B151 | ASME SB-151 | MIL-C-15726 |

| Cuni 70/30 Rod, Welding | AWS A5.15 |

| Density @ 68° F | 0.323 lb/in3 |

| Melting Range | 2140-2265o F |

| Hot Formability | Good |

| Cold Formability | Good |

| Machinability rating (C360 = 100) | 20 |

| Brazing | Excellent |

| Soldering | Excellent |

| Gas-shielded arc welding | Excellent |

| Oxy-acetylene welding | Good |

| Carbon-arc welding | Not recommended |

| Coated metal-arc welding | Good |

| Resistant welding: spot and seam | Good |

| Resistance Welding: butt | Good |

COMMERCIAL

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon |

|---|---|---|---|---|---|---|---|---|---|

| C71500 | remainder | 29.0-33.0 | 1.0 max | 0.05a max | 0.40-1.0 | 1.0a | |||

| C71520 | 65.0 min | 29.0-33.0 | 1.0 max | 0.02 | 0.40-1.0 | 0.5 | 0.02 max | 0.02 max | 0.05 max |

MIL-C-15726

| UNS No. | Copper | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | Cu + plus elements with specific limits, min |

|---|---|---|---|---|---|---|---|---|---|---|

| C71500 | 65.0 min | 29.0-33.0 | 1.0 max | 0.02 max | 0.40-1.0 | 0.50 max | 0.02 max | 0.02 max | 0.05 max | 99.5 |

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon | Cu + plus elements with specific limits, min |

|---|---|---|---|---|---|---|---|---|---|---|

| C71500 | 65.0 min | 29.0-33.0 | 1.0 max | 0.02 max | 0.40-1.0 | 0.50 max | 0.02 max | 0.02 max | 0.05 max | 99.5 |

| UNS No. | Copper + Silver | Nickel + Cobalt | Manganese | Lead | Iron | Zinc | Phosphorus | Sulfur | Carbon |

|---|---|---|---|---|---|---|---|---|---|

| C71500 | remainder | 29.0-33.0 | 1.0 max | 0.02 max | 0.40-1.0 | 0.50 max | 0.02 max | 0.02 max | 0.05 max |

NAVINIC 30® CuNi30Mn1Fe | ||

|---|---|---|

| STANDARD | EN12163 / EN12165 / EN12167 / EN12420 DIN17672 BS2874 DEFSTAN 02-879 ANNEX B / NES780 / DEF STAN 02-780 STF 2255 / B007 | |

| EUROPE | MATERIAL STANDARD | CW354H 2.0882 CN107 |

| DELIVERY CONDITION | M / R370 / .1O / O / M | |

| STANDARD | ASTM B122 / ASTMB124 / ASTM B151 / ASTMB171 MILC 15726F / MILC 24679SH | |

| UNITED STATES | MATERIAL STANDARD | UNS C71500 / UNS C71520 |

| DELIVERY CONDITION | O / O60 / H01 / M30 |

* CG - Centerless Ground HR RT - Hot Rolled Rough Turned | 3/16 CG 70/30 Cu-Ni Bar 1/4 CG 70/30 Cu-Ni Bar 5/16 CG 70/30 Cu-Ni Bar 3/8 CG 70/30 Cu-Ni Bar 1/2 CG 70/30 Cu-Ni Bar 5/8 CG 70/30 Cu-Ni Bar 3/4 CG 70/30 Cu-Ni Bar 13/16 CG 70/30 Cu-Ni Bar 7/8 CG 70/30 Cu-Ni Bar 1 CG 70/30 Cu-Ni Bar 1-1/8 CG 70/30 Cu-Ni Bar 1-1/4 CG 70/30 Cu-Ni Bar 1-3/8 CG 70/30 Cu-Ni Bar 1-1/2 CG 70/30 Cu-Ni Bar 1-3/4 CG 70/30 Cu-Ni Bar | 2 CG 70/30 Cu-Ni Bar 2-1/4 CG 70/30 Cu-Ni Bar 2-1/2 CG 70/30 Cu-Ni Bar 2-3/4 CG 70/30 Cu-Ni Bar 3 CG 70/30 Cu-Ni Bar 3-1/4 CG 70/30 Cu-Ni Bar 3-1/2 CG 70/30 Cu-Ni Bar 4 HR RT 70/30 Cu-Ni Bar 4-1/2 HR RT 70/30 Cu-Ni Bar 5 HR RT 70/30 Cu-Ni Bar 6 HR RT 70/30 Cu-Ni Bar 7 HR RT 70/30 Cu-Ni Bar 8 HR RT 70/30 Cu-Ni Bar 9 HR RT 70/30 Cu-Ni Bar 10 HR RT 70/30 Cu-Ni Bar |

US $10.00-$50.00 / Kilogram

Above is an approx price, please contact for final price of 70/30 Copper Nickel Bar

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cupro Nickel 70/30 | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| STANDARD | WERKSTOFF NR. | UNS |

| Cupro Nickel 70/30 | 2.0882 | C71500 |

| Cupro Nickel 70/30 Bright Bar | UNS C71500 Cu-Ni Bright Bar |

| Cu-Ni 70/30 Hex Bar | UNS C71500 Cu-Ni Hexagonal Bar |

| Cupro Nickel 70/30 Square Bar | ASTM B151 70/30 Cupro Nickel Hex Bar |

| ASTM B151 70/30 Bright Bar | Copper Nickel 70/30 Bright Bar |

| Cupro Nickel 70/30 Hex Bar | 70/30 Copper Nickel Hex Bar |

| Cupro Nickel 70/30 Square Bar | 70/30 Copper Nickel Hexagonal Bar |

| WERKSTOFF NR. 2.0882 Rectangular Bar | Cupro Nickel 70/30 Rectangular Bar |

| 70/30 Copper Nickel Square Bar | Cupro Nickel70/30 Threaded Bar |

| Copper Nickel 70/30 Flat Bars | Cupro Nickel 70/30 Polished Bar |

| 70/30 Copper Nickel Polished Bar | ASTM B151 70/30 Cupro Nickel Square Bars |

| WERKSTOFF NR. 2.0882 Square Bar | DIN NR. 2.0882 Threaded Bar |

| 70/30 Cu-Ni Threaded Bars | ASTM B151 70/30 Cu-Ni Rectangular Bar |

| Cu-Ni 70/30 Rectangular Bar | 70/30 Copper Nickel Rectangular Bar |

| UNS C71500 Copper Nickel Threaded Bar | 70/30 Cu-Ni Flat Bars |

| 70/30 Cupro Nickel Rectangular Bars | Cu-Ni 70/30 Polished Bar |

| UNS C71500 Cu-Ni Square Bar | 70/30 Cu-Ni Square Bars |

| UNS C71500 Copper Nickel Rectangular Bars | WERKSTOFF NR. 2.0882 Flat Bars |

| Cupro Nickel 70/30 Flat Bar | WERKSTOFF NR. 2.0882 Polished Bar |

| Cupro Nickel 70/30 Threaded Bar | 70/30 Cupro Nickel Threaded Bar |

| 70/30 Copper Nickel Polished Bars | ASTM B151 70/30 Copper Nickel Flat Bars |

| ASTM B151 70/30 Cupro Nickel Polished Bar | ASTM B151 70/30 Cu-Ni Threaded Bar |

| 70/30 Cupro Nickel Flat Bars | UNS C71500 Cu-Ni Flat Bars |

| UNS C71500 SS Polished Bars | CuNi C71500 Bus Bars |

Feel free to connect with us and get solutions and price quote in an instant.

Turkey, Singapore, Thailand, Philippines, Brazil, Greece, Italy, Egypt, Finland, Germany, Korea, Bahrain, USA, India, Spain, Poland, Netherlands, Romania, UK, Australia, UAE, South Africa, Malaysia, Canada, Russia, Mexico, Norway, Sweden, France, Saudi Arabia