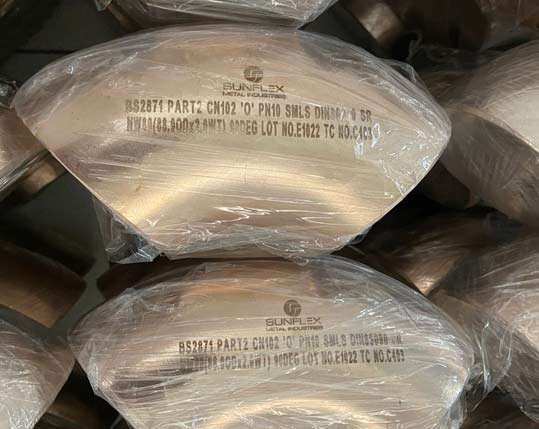

- SMI Copper (Sunflex Metal Industries)

- Download Catlogue

If you want to know What is Copper Nickel 70/30 Pipe Fittings, then here is the answer. It is a pipe fitting made up of an alloy that contains 70% copper, 30% nickel, and trace amounts of other elements like manganese and iron, in its chemical composition. Due to the chemical properties of the UNS C71500 Fittings, they have enhanced strength and corrosion resistance. The 70/30 Copper Nickel Pipe Fittings possess several properties, which is why they are popular across different industries.

Some features of the CuNi 70/30 Stub End would include good mechanical strength and rugged construction. They also have high toughness and can resist erosion effectively. The Copper Nickel 70/30 Tee is also known for possessing high tensile strength and can effectively resist pitting and oxidation. They also resist cracking due to stress corrosion and crevice corrosion. The 7030 Copper Nickel End Cap shows good high temperature performance and is quite long lasting too. They are well-known for their durability. It is to be noted that the corrosion resisting capabilities of the ASTM B466 UNS C71500 material is improved when there is high velocity water or polluted seawater. The UNS C71500 Reducer is basically cold worked and they come with high weldability and fabricability.

Due to all these properties of the CuNi 70/30 Saddle, they are highly demanded across several industries. The antifouling property of the Cupro Nickel 70/30 Equal Tee makes it perfect for seawater environments. The DIN 2.0882 Tee Fittings creates a thin layer of a protective film which does not allow marine life to grow on the pipe walls. This is why the 7030 Cupro Nickel End Caps are used in different business sectors.

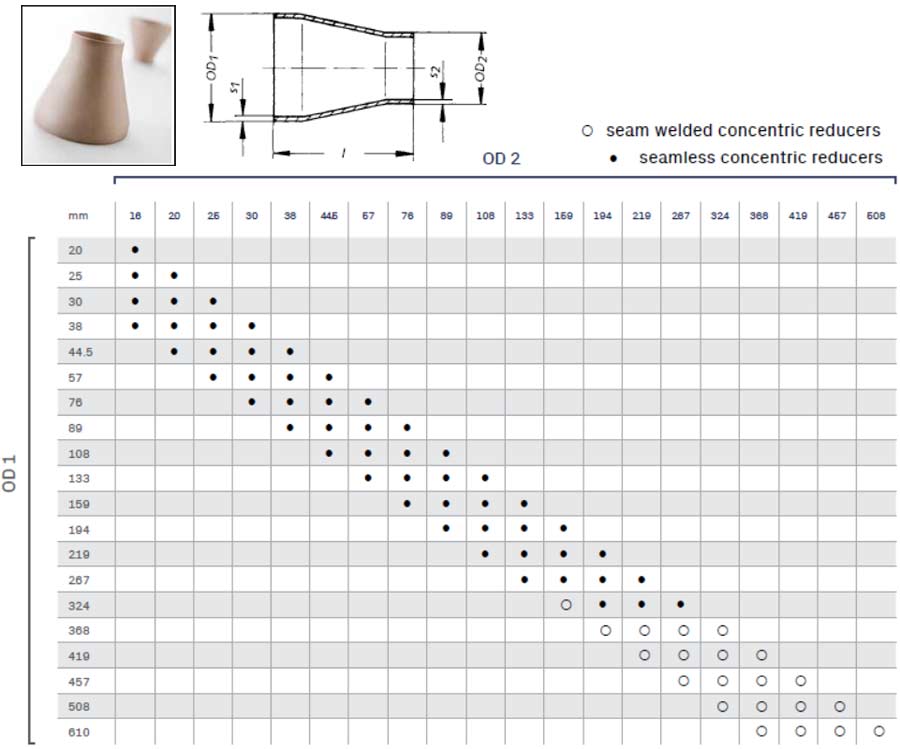

The 70 30 Nickel Copper Alloy Stub End shows moderate performance at elevated temperatures. They are thermally stable and the 70/30 Cu Concentric Reducers show good performance when it comes to corrosion resistance. It does not get affected by seawater and that is why the CW354H Reducing Tee is preferred for various seawater equipment.

As the CuNi30mn1fe Pipe Fittings have high fabricability and hence they can be fabricated using standard procedures. They can also be welded without any special considerations. The Cunifer 70/30 Buttweld Fittings can resist high temperature situations and hence they are used in various drilling type equipment, which are primarily used for extracting marine life from deep within the sea.

Copper Nickel 70/30 Fittings thermal conductivity (@20°C/ 68°F ) is 29 W/mK (201 BTU in/hr.ft².°F). 70/30 Cupro Nickel Fittings has a Charpy Impact of 107 J (78.9 ft-lb). The Shear Modulus of Cu-Ni 70/30 Buttweld Fittings is 57.0 GPa (8270 ksi). The Elastic Modulus of ASME B16.9 UNS C71500 Fittings is 150 GPa (21800 ksi). 70/30 Copper Nickel Pipe Bend have superb resistance to corrosion and pitting, in marine atmospheres. These fittings are available in different sizes and they can also be tailor-made to meet specific needs. Such Buttweld Fittings that are made from Copper Nickel 70/30 are famous for their superior tensile strength, flexibility, trouble free installation and maintenance and high corrosion resistance.

Rigid quality testing is done of fittings made of Copper Nickel 70/30 and this includes the likes of Pitting Resistance Test, Hardness Test, Flattening Test, Mechanical Testing such as Tensile of Area, Flaring Test, Positive Material Identification – PMI Testing, Chemical Analysis – Spectro Analysis, Intergranular Corrosion (IGC) Test and Micro and MacroTest. Cu-Ni alloy 70/30 5D Bend price can easily be found by searching online for suppliers, retailers, wholesalers and exporters of this product. The Elongation at Break (in 381 mm) of Cu-Ni 70/30 Seamless Pipe Fittings is 45.0%. The Poisson’s Ratio of Copper Nickel 70/30 is 0.34. WERKSTOFF NR. 2.0882 Butt Welding Fittings are strong and ductile. These 70/30 Cu-Ni Butt Welding Fittings are used salt water piping, off-shore oil drilling companies, salt water applications, pump bodies, petrochemical industries, salt water flanges, pharmaceutical equipment, heat exchangers, power generation, sea water equipment, gas processing, condensers, specialty chemicals, pulp and paper industry and in chemical equipment

| Size in Inch | |||

|---|---|---|---|

| 0.5 | 2.5 | 8 | 20 |

| 0.75 | 3 | 10 | 22 |

| 1 | 3.5 | 12 | 24 |

| 1.25 | 4 | 14 | |

| 1.5 | 5 | 16 | |

| 2 | 6 | 18 | |

| Standard Specification | ASME-B16.9, MIL-T-16420K, EEMUA-146, MSS-SP97, MSS-SP43, DIN86090, DIN28011, DIN86088 |

| Trade Name | Copper Nickel 70/30 Pipe Fittings |

| Other Trade Name | ASTM B466 UNS C71500, CuNi 70/30, CW354H, CuNi30mn1fe, DIN 2.0882, Cunifer 70/30, 70/30 Cu Fittings |

| Pressure Rating |

|

| Manufacturing size range of Copper Nickel 70/30 Buttweld Fittings | 1/2" - 24" DN15-DN500 OD 20 to OD 508 or custom |

| Thickness | 1.5 to 15mm |

| Schedule Sizes | SCH5/ 5S, SCH10/ 10S, SCH40/ 40S, STD, SCH80, SCH160 |

| Material Test Certificates (MTC) | All Copper Nickel 70/30 Pipe Fittings material supplied with MTC EN 10204 3.1, 3.2 |

| Manufacturing Type | Manufacturing Size | Price List in India |

|---|---|---|

| 70 30 Nickel Copper Alloy Reducer, concentric | DN150 * DN100 | FOB Price: US $ 24 - US $ 25 per Kg |

| CuNi 70/30 Tee, Buttweld, Reducing | 133 * 76.1MM * 3.0/2.5MM | FOB Price: US $ 19 - US $ 20 per Kg |

| 7030 Cupro Nickel Buttweld Tee Fittings, Reducing | 159 * 57MM * 3.0/2.0MM | FOB Price: US $ 26 - US $ 27 per Kg |

| Copper Nickel 70/30 Reducing Tee | 159mm * 44.5mm * 3.0/2.0 mm | FOB Price: US $ 19 - US $ 20 per Kg |

| 7030 Copper Nickel Buttweld Tee, Reducing | 76.1 mm * 38mm * 3.0/2.0mm | FOB Price: US $ 28 - US $ 30 per Kg |

| Cuni 70/30 Fittings | 159,0 X 2,5 MM | FOB Price: US $ 19 - US $ 20 per Kg |

| ASTM B466 UNS C71500 Tee, Reducing | Size in mm: 219.1 * 4/108 * 3 | FOB Price: US $ 34 - US $ 35 per Kg |

| UNS C71500 Tee Fittings, BW, Reducing | 76.1 mm * 44.5mm * 3.0/2.0mm | FOB Price: US $ 19 - US $ 20 per Kg |

| Cupro Nickel 70/30 Tee Fittings, Buttweld, Reducing | 76.1 * 44.5MM * 3.0/2.0MM | FOB Price: US $ 32 - US $ 33 per Kg |

| Cunifer 70/30 Buttweld Reducing Tee | 133 * 88.9MM * 3.0/3.0MM | FOB Price: US $ 19 - US $ 20 per Kg |

| 70/30 Cu Tee, Buttweld Type, Reducing | 133 * 108/3 * 3MM BW RED.TEE | FOB Price: US $ 18 - US $ 19 per Kg |

| Copper Nickel 70/30 Reducer, concentric | DN100 * DN80 | FOB Price: US $ 34 - US $ 35 per Kg |

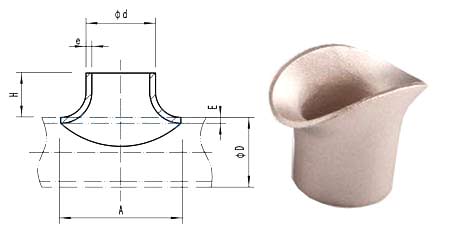

| OD * OD | OD * OD | Centre to face | Wall thickness | Theoretical weight | ||||||

| actual size | nominal size | H | A | E | e | Kg/ pcs | ||||

| mm | inch | mm | mm | mm | mm | |||||

| 38 | x | 38 | 1.25 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.18 |

| 44.5 | x | 38 | 1.5 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.23 |

| 44.5 | x | 44.5 | 1.5 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.25 |

| 57 | x | 38 | 2 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.25 |

| 57 | x | 44.5 | 2 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.28 |

| 57 | x | 57 | 2 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.4 |

| 76.1 | x | 38 | 2.5 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.37 |

| 76.1 | x | 44.5 | 2.5 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.42 |

| 76.1 | x | 57 | 2.5 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.6 |

| 76.1 | x | 76.1 | 2.5 | x | 2.5 | 50 | 126 | 2.5 | 2.5 | 0.65 |

| 88.9 | x | 38 | 3 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.45 |

| 88.9 | x | 44.5 | 3 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.55 |

| 88.9 | x | 57 | 3 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.62 |

| 88.9 | x | 76.1 | 3 | x | 2.5 | 50 | 126 | 2.5 | 2.5 | 0.7 |

| 88.9 | x | 88.9 | 3 | x | 3 | 55 | 149 | 2.5 | 2.5 | 0.95 |

| 108 | x | 44.5 | 4 | x | 1.5 | 35 | 74 | 3 | 2.5 | 0.38 |

| 108 | x | 57 | 4 | x | 2 | 40 | 97 | 3 | 2.5 | 0.48 |

| 108 | x | 76.1 | 4 | x | 2.5 | 50 | 126 | 3 | 2.5 | 0.78 |

| 108 | x | 88.9 | 4 | x | 3 | 55 | 149 | 3 | 2.5 | 0.94 |

| 108 | x | 108 | 4 | x | 4 | 75 | 188 | 3 | 3 | 1.56 |

| 159 | x | 76.1 | 6 | x | 2.5 | 50 | 126 | 3 | 2.5 | 0.78 |

| 159 | x | 88.9 | 6 | x | 3 | 55 | 149 | 3 | 2.5 | 1.2 |

| 159 | x | 108 | 6 | x | 4 | 75 | 188 | 3 | 3 | 1.44 |

| 159 | x | 159 | 6 | x | 6 | 95 | 279 | 3 | 3 | 3.12 |

| 219.1 | x | 88.9 | 8 | x | 3 | 55 | 149 | 4 | 2.5 | 1.73 |

| 219.1 | x | 108 | 8 | x | 4 | 75 | 188 | 4 | 3 | 2.4 |

| 219.1 | x | 159 | 8 | x | 6 | 95 | 279 | 4 | 3 | 5.06 |

| 219.1 | x | 219.1 | 8 | x | 8 | 125 | 379 | 4 | 4 | 5.7 |

| 219.1 | x | 219.1 | 8 | x | 8 | 125 | 379 | 4 | 4 | 7.6 |

| 267 | x | 108 | 10 | x | 4 | 75 | 188 | 4.5 | 3 | 2.7 |

| 267 | x | 159 | 10 | x | 6 | 95 | 279 | 4.5 | 3 | 5.54 |

| 267 | x | 219.1 | 10 | x | 8 | 125 | 379 | 4.5 | 4 | 6.75 |

| 267 | x | 219.1 | 10 | x | 8 | 125 | 379 | 4.5 | 4 | 9.14 |

| 267 | x | 267 | 10 | x | 10 | 155 | 447 | 4.5 | 4.5 | 12.4 |

| 267 | x | 267 | 10 | x | 10 | 155 | 447 | 4.5 | 4.5 | 13.05 |

| 323.9 | x | 159 | 12 | x | 6 | 95 | 279 | 5.5 | 3 | 5.22 |

| 323.9 | x | 219.1 | 12 | x | 8 | 125 | 379 | 5.5 | 4 | 6.6 |

| 323.9 | x | 219.1 | 12 | x | 8 | 125 | 379 | 5.5 | 4 | 10.58 |

| 323.9 | x | 267 | 12 | x | 10 | 155 | 447 | 5.5 | 4.5 | 12.1 |

| 323.9 | x | 267 | 12 | x | 10 | 155 | 447 | 5.5 | 4.5 | 13.75 |

| 323.9 | x | 323.9 | 12 | x | 12 | 185 | 560 | 5.5 | 5.5 | 15.4 |

| 323.9 | x | 323.9 | 12 | x | 12 | 185 | 560 | 5.5 | 5.5 | 17.87 |

| 368 | x | 219.1 | 14 | x | 8 | 125 | 379 | 6.5 | 4 | 7.1 |

| 368 | x | 267 | 14 | x | 10 | 155 | 447 | 6.5 | 4.5 | 11.8 |

| 368 | x | 323.9 | 14 | x | 12 | 185 | 560 | 6.5 | 5.5 | 15.4 |

| 368 | x | 368 | 14 | x | 14 | 200 | 613 | 6.5 | 6.5 | 20.1 |

| 419.1 | x | 267 | 16 | x | 10 | 155 | 447 | 7 | 4.5 | 11.65 |

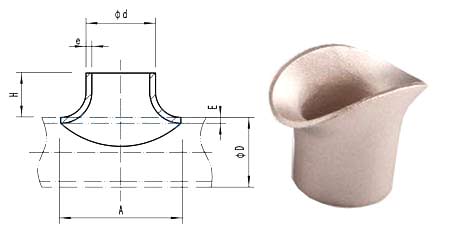

| OD * OD | OD * OD | Centre to face | Wall thickness | Theoretical weight | ||||||

| actual size | nominal size | H | A | E | e | Kg/ pcs | ||||

| mm | inch | mm | mm | mm | mm | |||||

| 38 | x | 38 | 1.25 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.18 |

| 44.5 | x | 38 | 1.5 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.23 |

| 44.5 | x | 44.5 | 1.5 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.25 |

| 57 | x | 38 | 2 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.25 |

| 57 | x | 44.5 | 2 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.28 |

| 57 | x | 57 | 2 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.4 |

| 76.1 | x | 38 | 2.5 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.37 |

| 76.1 | x | 44.5 | 2.5 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.42 |

| 76.1 | x | 57 | 2.5 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.6 |

| 76.1 | x | 76.1 | 2.5 | x | 2.5 | 50 | 126 | 2.5 | 2.5 | 0.65 |

| 88.9 | x | 38 | 3 | x | 1.25 | 35 | 64 | 2.5 | 2.5 | 0.45 |

| 88.9 | x | 44.5 | 3 | x | 1.5 | 35 | 74 | 2.5 | 2.5 | 0.55 |

| 88.9 | x | 57 | 3 | x | 2 | 40 | 97 | 2.5 | 2.5 | 0.62 |

| 88.9 | x | 76.1 | 3 | x | 2.5 | 50 | 126 | 2.5 | 2.5 | 0.7 |

| 88.9 | x | 88.9 | 3 | x | 3 | 55 | 149 | 2.5 | 2.5 | 0.95 |

| 108 | x | 44.5 | 4 | x | 1.5 | 35 | 74 | 3 | 2.5 | 0.38 |

| 108 | x | 57 | 4 | x | 2 | 40 | 97 | 3 | 2.5 | 0.48 |

| 108 | x | 76.1 | 4 | x | 2.5 | 50 | 126 | 3 | 2.5 | 0.78 |

| 108 | x | 88.9 | 4 | x | 3 | 55 | 149 | 3 | 2.5 | 0.94 |

| 108 | x | 108 | 4 | x | 4 | 75 | 188 | 3 | 3 | 1.56 |

| 159 | x | 76.1 | 6 | x | 2.5 | 50 | 126 | 3.5 | 2.5 | 0.91 |

| 159 | x | 88.9 | 6 | x | 3 | 55 | 149 | 3.5 | 2.5 | 1.4 |

| 159 | x | 108 | 6 | x | 4 | 75 | 188 | 3.5 | 3 | 1.68 |

| 159 | x | 159 | 6 | x | 6 | 95 | 279 | 3.5 | 3.5 | 3.64 |

| 219.1 | x | 88.9 | 8 | x | 3 | 55 | 149 | 4.5 | 2.5 | 1.94 |

| 219.1 | x | 108 | 8 | x | 4 | 75 | 188 | 4.5 | 3 | 2.7 |

| 219.1 | x | 159 | 8 | x | 6 | 95 | 279 | 4.5 | 3.5 | 5.69 |

| 219.1 | x | 219.1 | 8 | x | 8 | 125 | 379 | 4.5 | 4.5 | 6.4 |

| 219.1 | x | 219.1 | 8 | x | 8 | 125 | 379 | 4.5 | 4.5 | 8.55 |

| 267 | x | 108 | 10 | x | 4 | 75 | 188 | 5.5 | 3 | 3.3 |

| 267 | x | 159 | 10 | x | 6 | 95 | 279 | 5.5 | 3.5 | 6.77 |

| 267 | x | 219.1 | 10 | x | 8 | 125 | 379 | 5.5 | 4.5 | 8.25 |

| 267 | x | 219.1 | 10 | x | 8 | 125 | 379 | 5.5 | 4.5 | 11.17 |

| 267 | x | 267 | 10 | x | 10 | 155 | 447 | 5.5 | 5.5 | 15.15 |

| 267 | x | 267 | 10 | x | 10 | 155 | 447 | 5.5 | 5.5 | 15.95 |

| 323.9 | x | 159 | 12 | x | 6 | 95 | 279 | 7 | 3.5 | 6.64 |

| 323.9 | x | 219.1 | 12 | x | 8 | 125 | 379 | 7 | 4.5 | 8.4 |

| 323.9 | x | 219.1 | 12 | x | 8 | 125 | 379 | 7 | 4.5 | 13.46 |

| 323.9 | x | 267 | 12 | x | 10 | 155 | 447 | 7 | 5.5 | 15.4 |

| 323.9 | x | 267 | 12 | x | 10 | 155 | 447 | 7 | 5.5 | 17.5 |

| 323.9 | x | 323.9 | 12 | x | 12 | 185 | 560 | 7 | 7 | 19.6 |

| 323.9 | x | 323.9 | 12 | x | 12 | 185 | 560 | 7 | 7 | 22.74 |

| Manufacturer of | ASME/ ANSI Specification | Germany Standard |

|---|---|---|

| Copper Nickel 70/30 Welding Collars | ASME B16.9 | DIN 86037 |

| 7030 Copper Nickel Elbow Long Radius | ASME B16.9 | DIN 86090 |

| ASTM B466 UNS C71500 Elbow Short Radius | ASME B16.9 | DIN 86090 |

| UNS C71500 Equal Tee | ASME B16.9 | DIN 86088 |

| CuNi 70/30 Reducing Tee | ASME B16.9 | DIN 86088 |

| 7030 Cupro Nickel Concentric Reducer | ASME B16.9 | DIN 86089 |

| Cupro Nickel 70/30 Eccentric Reducer | ASME B16.9 | DIN 86089 |

| 70/30 Cu Equal Saddle | ASME B31.3 and B31.4 | DIN 86087 |

| Cunifer 70/30 Reducing Saddle | ASME B31.3 and B31.4 | DIN 86087 |

| 70 30 Nickel Copper Alloy End Cap | ASME B16.9 | DIN 28011 |

| Destructive Testing | Non Destructive Testing |

|---|---|

|

|

| Type of Copper Nickel 70/30 fitting | Size range | 16 bar rating Copper Nickel 70/30 fitting | 20 bar rating Copper Nickel 70/30 fitting | ||||||

| 38˚C | 50˚C | 75˚C | 100˚C | 38˚C | 50˚C | 75˚C | 100˚C | ||

| 7030 Copper Nickel Butt Weld fittings | 1 inch - 4 inch 30mm - 108mm |

Use 20 bar | 20.0 | 19.7 | 18.6 | 17.3 | |||

| ASTM B466 UNS C71500 Butt Weld fittings | 6in - 36in/ 159mm - 914mm |

16.0 | 16.0 | 16.0 | 15.7 | 20.0 | 19.7 | 18.6 | 17.3 |

| UNS C71500 Socket weld fittings | ½in/ - 2in 16mm - 57mm |

Use 20 bar | 20.0 | 19.7 | 18.6 | 17.3 | |||

| CuNi 70/30 Capillary brazed fittings | ½in/ - 2in 16mm - 57mm |

20.0 | 19.7 | 18.6 | 17.3 | ||||

| 7030 Cupro Nickel Compression fittings | ½in/ - 2in 16mm - 57mm |

- | - | - | - | ||||

Feel free to connect with us and get solutions and price quote in an instant.

Turkey, Singapore, Thailand, Philippines, Brazil, Greece, Italy, Egypt, Finland, Germany, Korea, Bahrain, USA, India, Spain, Poland, Netherlands, Romania, UK, Australia, UAE, South Africa, Malaysia, Canada, Russia, Mexico, Norway, Sweden, France, Saudi Arabia